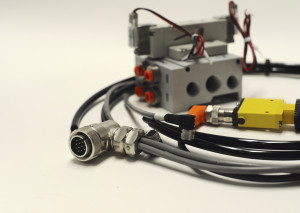

Sensor Cable

Galaxy supplies a full range of custom sensor cables, including vented and unvented multi-conductor cables for various sensor, transducer, and transmitter markets.

Galaxy Differentiators / Advantages for Sensor Cable

Galaxy designs and supplies numerous sensor cables for a number of industries, with the understanding that the sensor cable can be the critical difference between whether a piece of equipment works or not. Galaxy knows the materials and constructions that will achieve the perfect custom cable solution for a specific end use, ensuring that reliable signal transmissions or electrical readings will be met.

Galaxy designs and supplies numerous sensor cables for a number of industries, with the understanding that the sensor cable can be the critical difference between whether a piece of equipment works or not. Galaxy knows the materials and constructions that will achieve the perfect custom cable solution for a specific end use, ensuring that reliable signal transmissions or electrical readings will be met.

Galaxy Success Story – Case Study

A potential new customer came to Galaxy looking for a sensor cable to be used in a seismic sensor application. Previously the end user had been combining two different name brand cables to accomplish this objective. While this two-cable setup was “working”, the engineering team knew it would not be a long term solution. After discussing the project and their goals with Galaxy, a newly designed sensor cable was manufactured. The cost of the newly designed cable was lower than the previous two-cable setup. Most importantly, the customer was able to take their product to market with great success.

Insulation and Jacketing Materials

Sensor cable and wire from Galaxy is available with the following materials:

- Polyethylene

- Polyurethane

- FEP

- ETFE Tefzel®

- Hytrel®

| Material | Abrasion Resistance | Flexibility | Voltage Breakdown | Weather -ability | Nominal Temp Range C | Alcoho-glycol | Nominal Dielectric Constant | Gasoline | Tichloro -ethylene |

|---|---|---|---|---|---|---|---|---|---|

| Polyurethane | E | E | 500 | E | -50 to 80°C | G | 7 | G | G |

| Polyethylene | G | F | 600 | E | -60 to 80°C | G | 2.1 | G | G |

| Foam Polyethylene | P | G | N/A | E | -60 to 80°C | P | 1.5 | P | P |

| Nylon | E | E | 450 | E | -40 to 120°C | E | 4 | G | E |

| Hytrel | E | E | 860 | E | -50 to 105°C | G | 6 | G | G |

| FEP | E | E | 600 | E | -70 to 200°C | E | 2.1 | E | E |

| ETFE Tefzel | E | E | 400 | E | -70 to 150°C | E | 2.7 | E | E |

E = Excellent

G = Good

P = Poor

Sensor Cable Technical Specifications

Galaxy offers sensor cable in the following ranges of technical specifications:

- Gauge: 30AWG – 10AWG

- Voltage: Specific to application

- Temperature: -70 ⁰C – +200 ⁰C

- Shielding: Braid, Foil, Serve, or combination

- Strength Member: Kevlar or aramid fiber can be added to support weight strain on the cable

- Vent Tube: Hollow tube in center of cable to allow for changes in pressure without affecting the accuracy of the readings

FAQs about Sensor Cable

How do I select a cable insulation and jacket that are right for my application?

Many factors come into play here. It is necessary to consider temperature, voltage, abrasion resistance, flexibility, and chemical compatibility. Galaxy often works with customers to learn about where the cable will be used and what its function will be to help select the materials for optimum performance. See table above describing various choices/options.

What is the reason for a vent tube in a cable?

The vent tube can be made of either nylon or polyethylene and runs the length of the cable down its core. It allows for changes in atmospheric pressure so as not to affect the pressure reading in gauge type sensors.

Terminology Notes

There are various terms used in the wire and cable industry related to this type of cable. They include:

- Sensor Cable

- Transmitter Cable

- Transducer Cable

- Vented Cable

*Tefzel® and Hytrel® are registered trademarks of E. I. du Pont de Nemours and Company

Contact Galaxy Wire & Cable for Sensor Cable and Sensor Wire

Contact Galaxy for further assistance with custom sensor cable and wire.

Galaxy supplies a full range of vented and unvented multi-conductor cables for various sensor, transducer, and transmitter markets. Galaxy can supply various types of sensor cables, both stock and custom, in various AWG sizes, voltage ratings, compounds, shielding constructions, and conductor counts. Galaxy can also recommend the correct sensor cable for specific applications.

Galaxy supplies a full range of vented and unvented multi-conductor cables for various sensor, transducer, and transmitter markets. Galaxy can supply various types of sensor cables, both stock and custom, in various AWG sizes, voltage ratings, compounds, shielding constructions, and conductor counts. Galaxy can also recommend the correct sensor cable for specific applications.